"When do I plan maintenance to optimise up-time and minimize cost ?"

Maintenance is for a lot of capital-intensive businesses a huge cost. However, currently, most companies spend their maintenance budget in a suboptimal way.

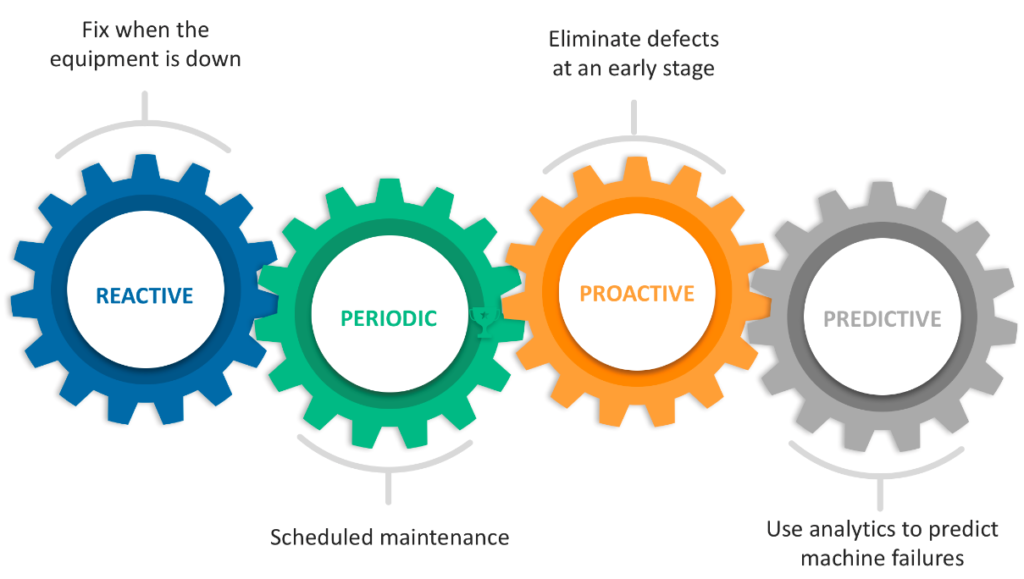

Maintenance can be organised based on

- a reactive model (i.e. equipment breaks down, you fix it)

- a periodic model (i.e. you have scheduled maintenance)

- or via a pro-active model (i.e. you perform maintenance on small defects in order to prevent your equipment from failing).

Those three methods all have in common that they all incur unnecessary costs: in case of the reactive model, you have downtime costs and often a longer time to resolution. In the periodic model, you generate maintenance costs that might not be needed because your equipment doesn't need a maintenance yet. In the pro-active model, you try to elimante defects at an early stage, with the risk of being too late and incurring big maintenance costs.

What is Predictive Maintenance?

According to the McKinsey report "The Internet of Things: Mapping the value beyond the hype", manufacturing companies can save 10-40 % in maintenance costs, reduce downtime with 50% as well as extend the lifetime of the equipment with 3-5%.

In order to generate these savings, companies need to start investing into Predictive Maintenance, i.e. using data-driven analytics to optimize their maintenance spend. This means you gather and analyze real-time data and historical data in order to go from a break-fix model to a predict-optimize model. Predictive maintenance will never replace the current maintenance methods (reactive - periodic - proactive) yet serve as an addition to your maintenance strategy optimizing your maintenance spend and the lifetime of your assets.

But how do you get started with predictive maintenance?

- Start from a business perspective. Start by (1) calculating how accurate you'll need to be to achieve your desired savings and (2) reflecting on what you would actually need to predict (and if this is measurable)

- Then do a data mapping exercise: what data do you have, what's tracked, how do I track it from now on, how do I validate if a prediction is correct, etc.

- Get started with a Proof of Concept and show through historical data it's feasible to be done

What can element61 help?

At element61, we've previously supported clients in setting up Predictive Maintenance. Through this experience and learning curve we can help you avoid mistakes and make your projects a success.

"We are convinced, that starting of with a Proof of Concept, we can already show you the added value Predictive Maintenance can bring to your organization."

- Ivana Pejeva, Data Scientist

Contact us to get started or read our predictive maintenance reference case for a real-life example of how this can be done.