Organization

Sabcobel is a refrigeration company which provides cooling elements for both the retail and industrial sector. The company was founded in 1958 and today has around 80 employees spread across Belgium and Luxembourg. They offer an end-to-end cooling solution to their clients, from design to implementation followed by a 24/7 monitoring of their systems.

Challenge

Sabcobel has hundreds of cooling installations to monitor and control. Each installation is critical as it controls the quality and lifespan of the products it contains (e.g. food products); as a result, the cooling needs to be closely monitored and - when temperature surges occur - timely addressed. Every cooling installation has sensors attached to their cooling elements in order to trigger an alarm in case of a defective cooling element. This allows Sabcobel to make a quick intervention to fix the defect. However, every defect results in repair activities as well as downtime costs for the customer which are costs they want to minimize. Therefore, Sabcobel was looking to change their maintenance organization from this break-fix model to a prevent-optimize model where they would predict the failure of a system and perform a preventive fix in order to minimize the repair costs and downtime for their customers.

Solution

Sabcobel worked with element61 to set up a system to have

- a real-time monitoring system for all their assets and

- predictive maintenance in place to predict installation failures & alerts before they occur.

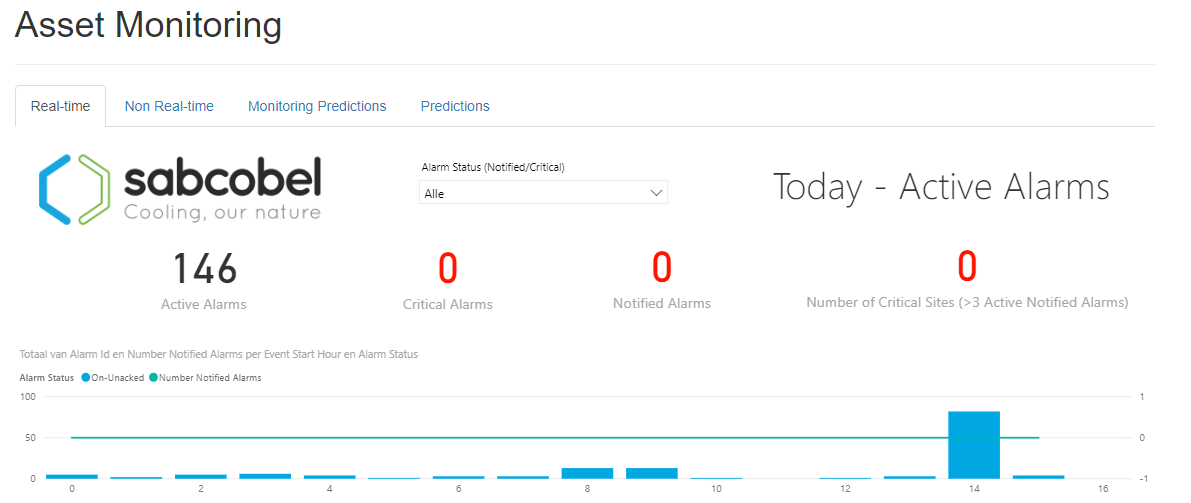

Initially, a monitoring system was put in place using Microsoft PowerBI to give the customer interactive reporting capabilities with proactive notifications of failing systems. Secondly, using all historical data available, a Machine Learning prediction model was built in Microsoft Azure to predict when an alarm would be triggered, but also what the cause of an alarm would be. The latter was an important factor so Sabcobel is able to understand whether a predicted alarm would really result in a failure and a technician needs to be sent or whether it could be easily solved remotely.

Figure 1. example of an interactive dashboard

As part of the predictive tool, element61 has built in a feedback-loop which is used to indicate whether the predictions were correct or not. This important loop is incorporated in the solution to leverage the customer input towards improvements in the model performance. In order to guarantee that the tool is running continuously, we put a monitoring mechanism in place informing us in case of a failure of the prediction tool.

Result

By considering their data as a real valuable business asset, Sabcobel has been able to transform their service organization to a prevent-optimize organization. Sabcobel is now able to reduce their maintenance costs as well as limited the downtime for their customers which increases customer satisfaction.

“During the hot summer 2018, the monitoring system built by element61 already proved more accurate & responsive than our previously used alarm call center. This means the quality & responsiveness of our service is guaranteed even when it’s busy & pressure is high.”

- Matthias Coppens, Service Manager Sabcobel